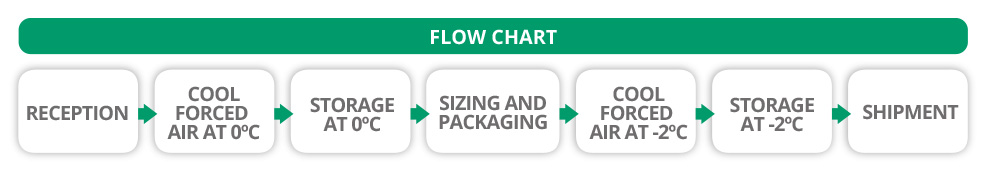

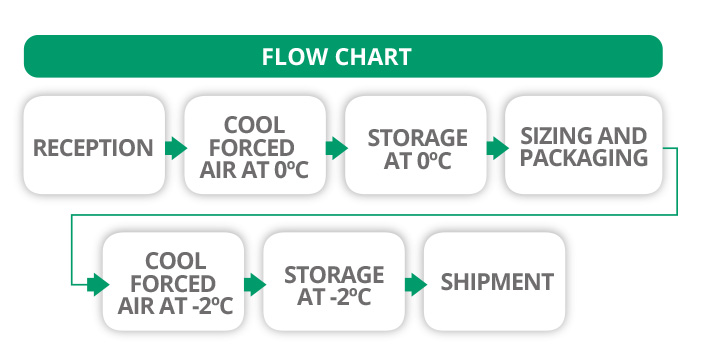

Once the chestnut are received and after a sample is taken for quality control, before an hour the chestnut are placed on cool forced air ftunnel to give the pulp temperature to 0ºC at the shortest time possible. After this, the fruit is stored separated by conventional and organic in cool chambers at 0ºC waiting to the next process.

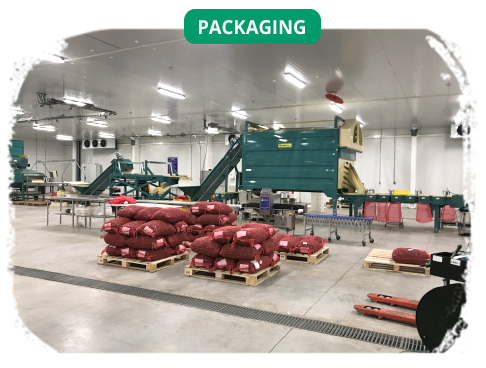

The next process is continuous processing line where the remaining dust and vegetal material that might remains, the chestnuts are brushed, hand sorted and then sized by equatorial length in mm.

The sized chestnuts and then packed in 25 kg plastic nets, palletized and then labeled by its size in mm. and/or by pieces per kg.

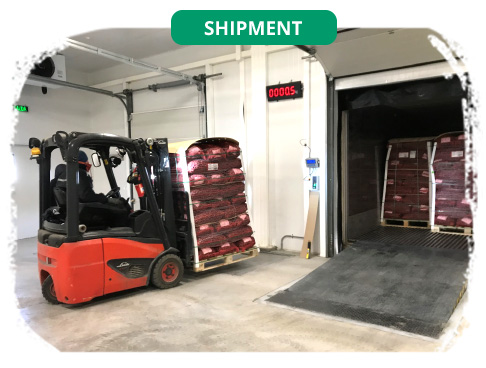

The palets with final products goes again to the cool forced air tunnel to bring the pulp temperature to the one required to travel. Before the shipment it is verified to check temperature, labeling, palet stability and other to the load into refrigerated containers.